One of the big things that Olam Agri has put in place as part of the CSR in Nigeria is the seed for the future. And one big part of it is to empower master bakers to become more efficient by promoting green atmosphere instead of fossil fuel.

We have put in place technology that will enhance efficient use of energy without necessarily compromising on the quality of the output.

Bread is one of the most popular and beloved staple foods in Nigeria. In recent years, prices of flour and other ingredients involved in making bread have gone up significantly as a result of inflation and constant devaluation of the naira. However, energy has been the toughest cost to manage and it has been responsible for at least 40-50% of total cost incurred by bread makers in Nigeria.

Power supply from the national grid cannot adequately cater for the energy requirement of businesses. The alternatives are coal, LPGs and fossil fuel power generators. The coal technology is old and not in use by modern bakeries. LPGs and fossil fuel generators go up tens of thousands of naira every day, thereby escalating cost. More than 20% of bakeries have had to shut down operations largely because they could no longer cope with the very high cost of running on diesel.

Primarily inspired by this problem, a team of researchers at Olam Agri went to work to develop a more cost-effective source of energy. That research has led to the discovery and development of the gasifier that runs on agri waste products like palm cannel shell, yam peel and several others that can be easily sourced at extremely cheap cost from farms all over Nigeria.

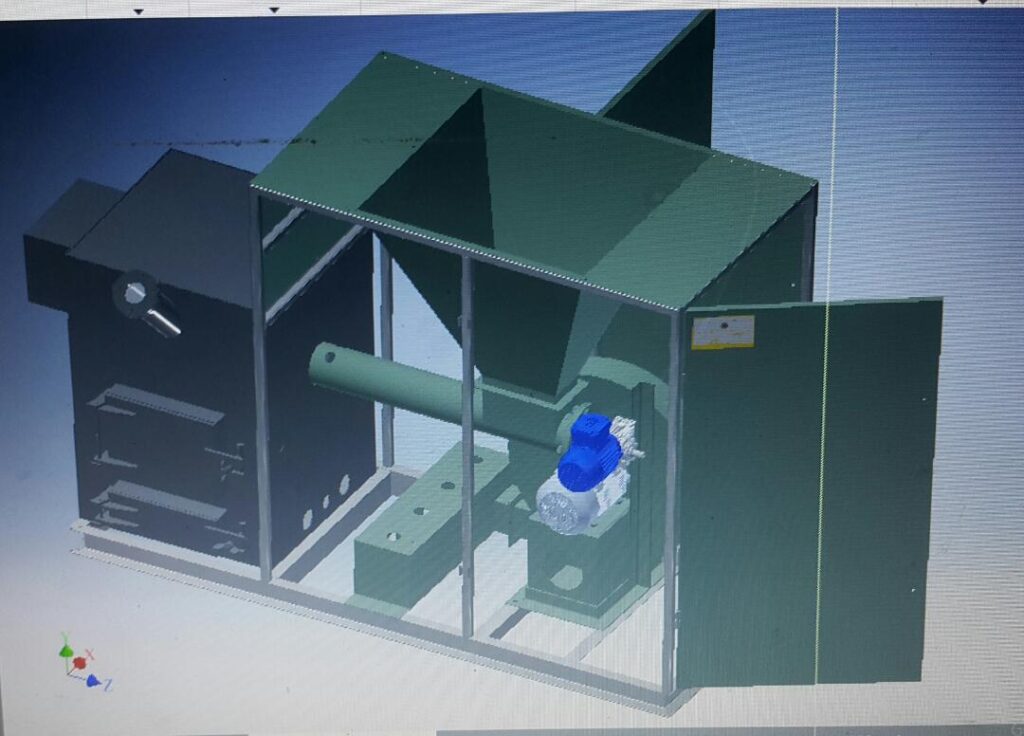

HOW DOES IT WORK?

The biomass gasifier simply works by the impute hopper receiving the biomass material itself, which is being transported through an auger to the combustion chamber where it is being composted. There is an aspiration farm that actuallysucks air from the environment and feeds into the combustion chamber to aid in the combustion process. This air that is sent into the combustion chamber helps in achieving complete oxidation of the biomass material itself. Using the gasifier is quite easy. Once the agri waste is loaded, the gasifier is good to go. The gasifier has a drying zone that dries up the biomass when loaded before feeding it into combustion zone.

The gasifier produces the required capacity and quality of energy required by bakers at a far cheaper cost and it also produces cleaner energy compared to the fossil fuel. Olam Agri carried out a test run of the gasifier in four bakeries and the result has been phenomenal. The gasifier has been able to help local bread makers reduce cost of energy generation by at least 75%.

Olam Agri is eager to help bakers across Nigeria to develop the gasifier in order to help them reduce the cost of generating energy, thereby making business more lucrative.

The Olam Agri team is hoping to promote the usage of the gasifier across several industries and even for more domestic usage energy generation. This, we are convinced, will help reduce high cost of production, improve the business terrain, improve employment and create a new value chain that will empower many young Nigerians.

Beyond being an additional income poll for Olam Agri, this project is part of our contribution towards helping Nigeria meet its millennium development goals of net zero carbon. This initiative will no doubt reduce carbon emission into the ecosystem and make it a better and healthier place for everyone.